Leak Testing Using Mass Flow

The mass flow leak test method is characterized by the direct measurement of the result in cm³/min. This is calculated with the volume factor (ratio between test and reference volume) and output as leakage rate. Thermal mass flow sensors or laminar flow elements are usually used as sensors.

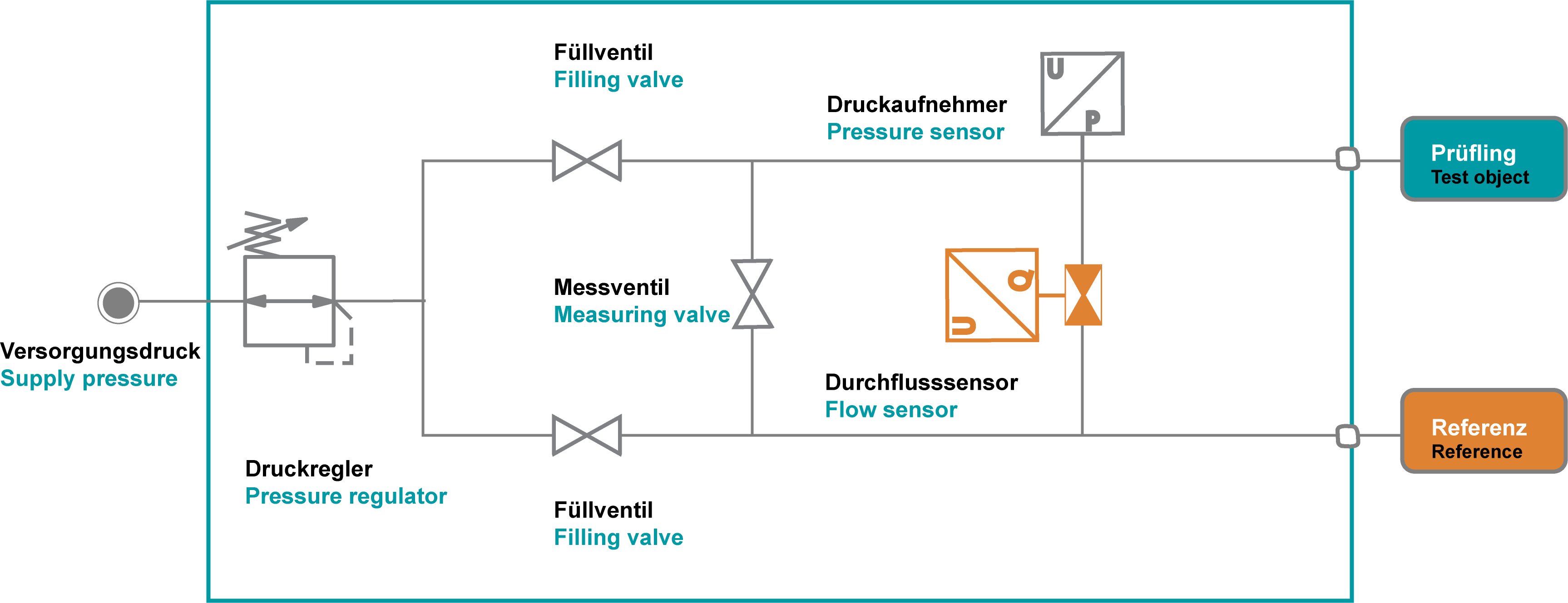

During the test, the test specimen and the reference volume are simultaneously filled with positive or negative pressure. After the stabilization phase, the flow direction and mass flow between the two volumes is determined.

Due to the high accuracy and the compensation of volume and temperature fluctuations, mass flow is particularly suitable for large-volume components such as fuel tanks, battery housings, car body parts, large cooling systems, inverter housings, and more.

Test medium:

Compressed air/vacuum or nitrogen

Detectable leak rates:

Volume and pressure dependent > 0.5 cm3 / min

Method:

Test item is subjected to pressure/vacuum. The air escaping due to leakage is compensated via a reference volume. The compensation flow is determined via a mass flow meter and is a measure of the leakage rate.

Advantages:

- Low operating costs

- Complete detection of the leakage rate, even with large volumes small leakage rates of a few cm³ / min can be measured

- Relatively short measuring time possible, as the response time of the sensor system is < 1 sec

Disadvantages:

- More effort in the measuring device due to the required reference

- The ratio of reference volume to test sample volume should not exceed 5:1, otherwise small fluctuations lead to a large measurement difference