Pressure Differential Method

The pressure differential method with reference volume is by far the most widely used method in leak testing.

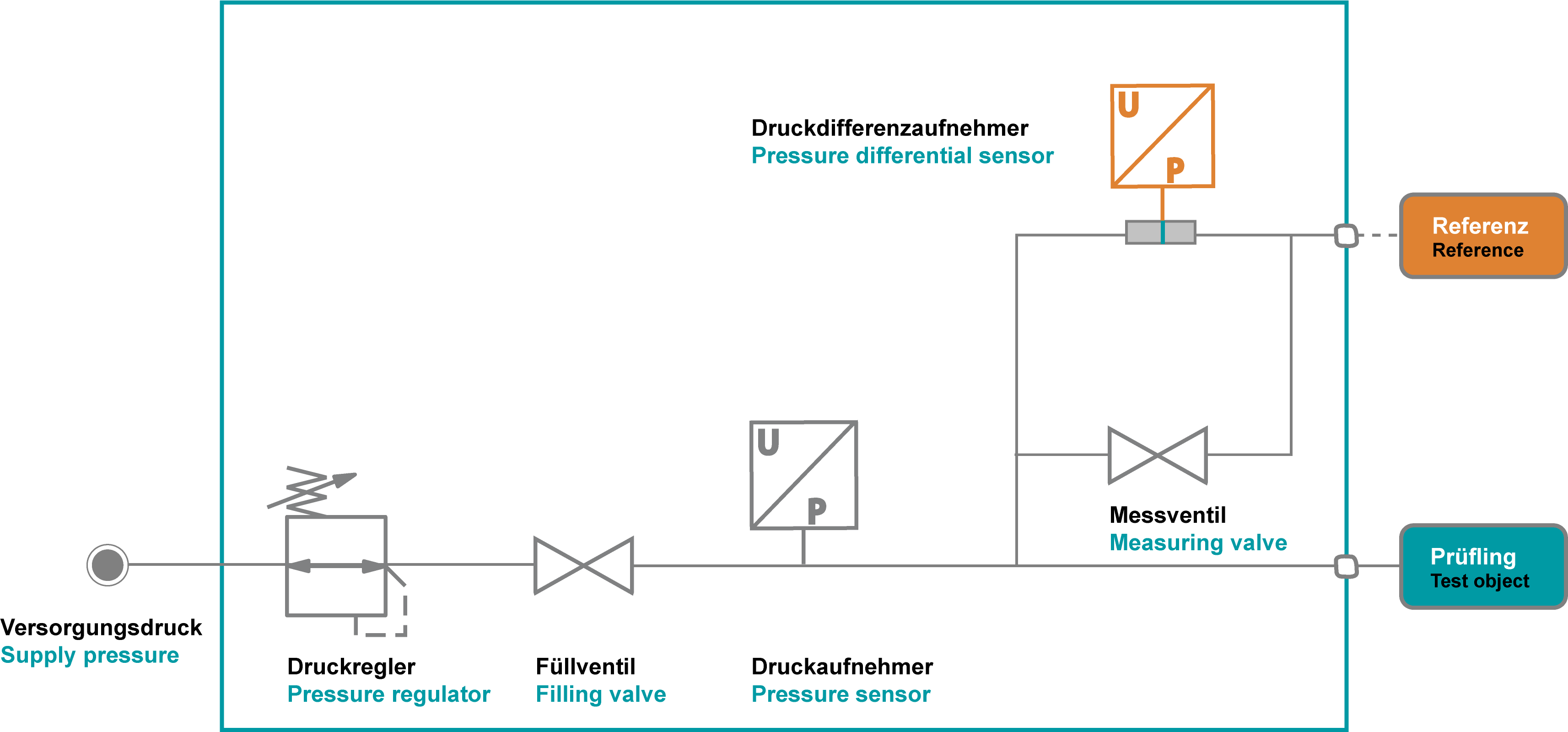

In the pressure differential method, pressure is applied to a reference volume in addition to the test item. The reference volume can be either a small internal volume or, for example, a master test specimen. After the stabilization time, the pressure change between these two volumes is measured by a highly sensitive pressure difference sensor.

An additionally installed absolute or relative pressure sensor only monitors the pressure in the test specimen. This allows the test pressure to be adjusted either absolutely to the ideal vacuum or relative to the ambient pressure and checked for rough leakage.

Since the pressure differential sensor is pressurized from both sides, high test pressures can also be realized with very accurate measurement resolution and low leakage rates. The static test pressure therefore plays almost no role here.

Typical applications for this test method are those with small volumes that require fast test times, including cooling ducts, cooling hoses, electrical connectors and membranes.

Test medium:

Compressed air/vacuum, nitrogen, hydrogen, helium

Detectable leak rates:

Depending on volume and pressure > 1 cm³ / min

For very small volumes also < 1 cm³ / min

Method:

Pressure/vacuum is applied to the test specimen. The pressure change in the test item caused by leakage is measured and evaluated against a reference via a differential pressure transducer.

Advantages:

- Low investment

- Low operating costs

- Complete detection of the leakage rate

- All features as with the absolute pressure method

- Good measuring signal resolution, even at high test pressure

- External reference volume also advantageous for elastic parts, as better compensation of volume expansion

- Reference volume under the same thermal conditions ensures short cycle times

Disadvantages:

- Sensitive to temperature changes and other environmental influences

- Can only be effective at small leakage rates and large volumes (e.g., 150 mbar; 50 ml/min; 20 l volume), not suitable for large pressure drops or burst tests