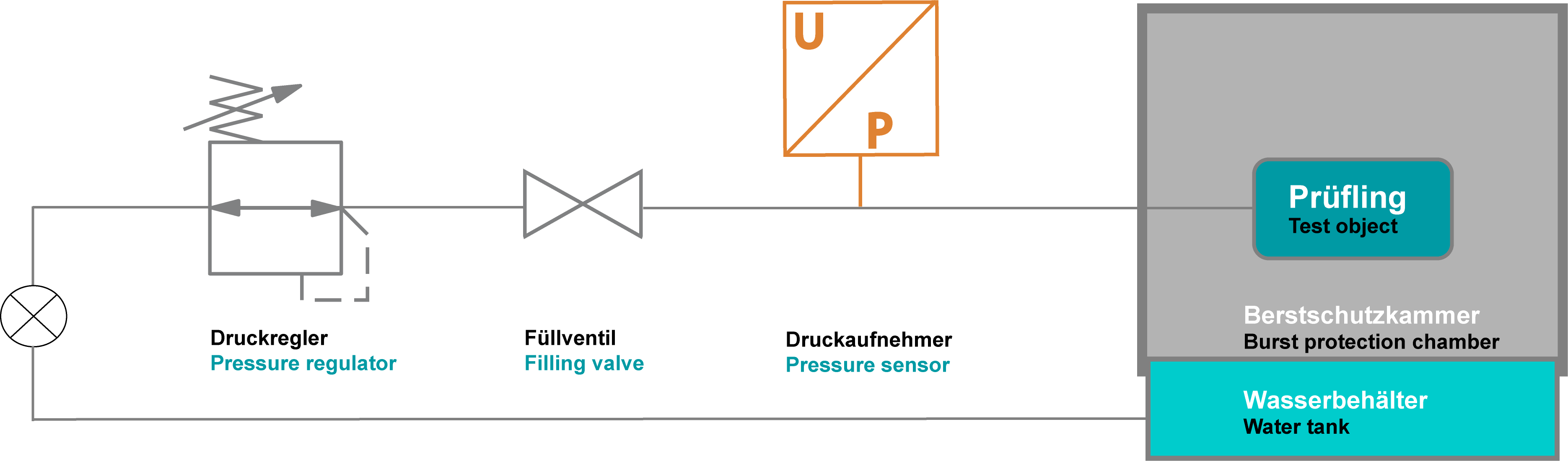

Bursting Pressure Test with Water or Oil

The bursting pressure test method with water or oil allows very high bursting pressures, even with large volumes.

The test specimen is filled with the bursting medium and must be vented as best as possible. Larger air pockets must be avoided by technical measures such as pre-evacuation, flushing and special component positioning, as these store energy in the form of compressed gas.

The pressure increase can be pulsating or uniform via a ramp. Depending on the desired sampling rate and accuracy, this can be displayed as a pressure value over time in a graph.

Special hardware makes it possible to combine fast pressure increase ramps with high pressure control.

Depending on the medium, the systems are built so that the medium can be reused through filtration and intermediate storage.

Although the stored energy within the component is significantly lower than in the case of burst testing systems with air, the testing systems must be designed and constructed in accordance with the applicable safety guidelines. The safety of the operator is the top priority here.

Test medium:

Water/oil

Burst pressures:

Stepless from 0.01 - 1,000 bar (maximum test pressure depending on component volume)

Method:

The test specimen is filled with the test medium and caused to burst. The bursting point or the pressure curve is recorded by the system.

Advantages:

- Very accurate method for function and burst testing

- Low stored energy allows very high test pressures even with large volumes

Disadvantages:

- Handling of water/oil requires special system design and filter techniques

- Venting of the test specimen is sometimes very complex and cost-intensive