Extend your Leak Test Computer with seamless communication, automation capabilities, and data management options

Our add-ons empower you to integrate testing deeply into your production environment—enabling remote operation, automated data transfer, and smooth connection to industrial control systems. With these function extensions, you optimize workflow efficiency, reduce manual effort, and future-proof your quality assurance processes.

Discover our network-enabled add-ons:

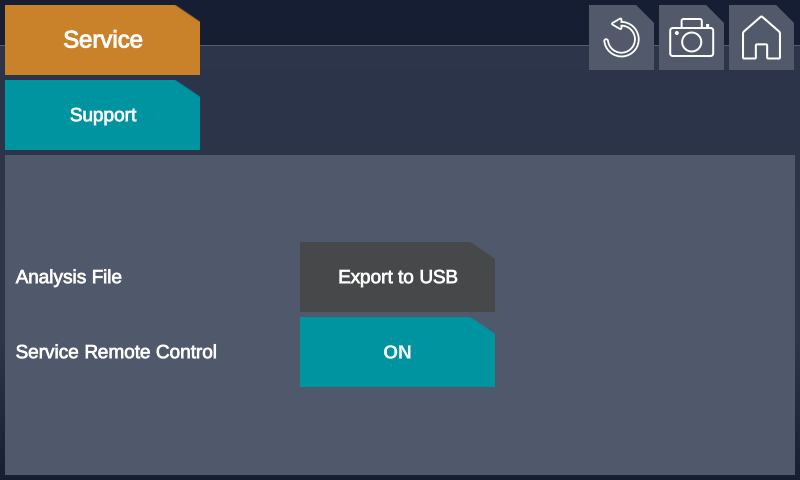

Remote Control - Operate Anywhere, Stay Connected

Operate and monitor your Leak Test Computer remotely via your existing LAN network—perfect for hard-to-reach test benches or centralized control stations. This software extension mirrors the LTC display on your PC or industrial panel and lets you control the device intuitively with mouse or touch input using a secure RDP connection. Start and stop tests virtually, with all actions visible on both local and remote displays. Available to add to the LTC-503, LTC-802 and LTC-902.

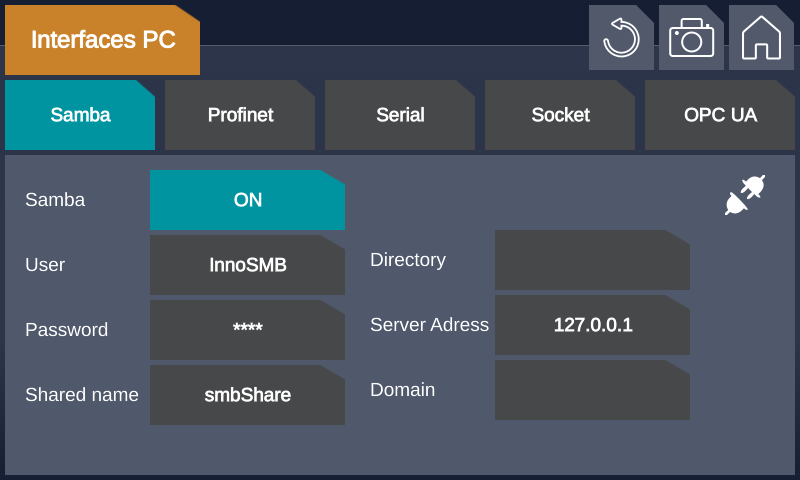

Automated Data Transfer - Seamless Backup, Zero Hassle

Automatically store measurement and graphic data from your LTC directly to a network file share (SMB/CIFS) on a defined server for streamlined documentation and centralized archiving - efficiently, securely and without user intervention. This extension transfers test results and histories to your server in the background—buffering data locally during connection outages and signaling any transfer issues for easy fault detection. Available for all LTC models (LTC-503, LTC-802, and LTC-902).

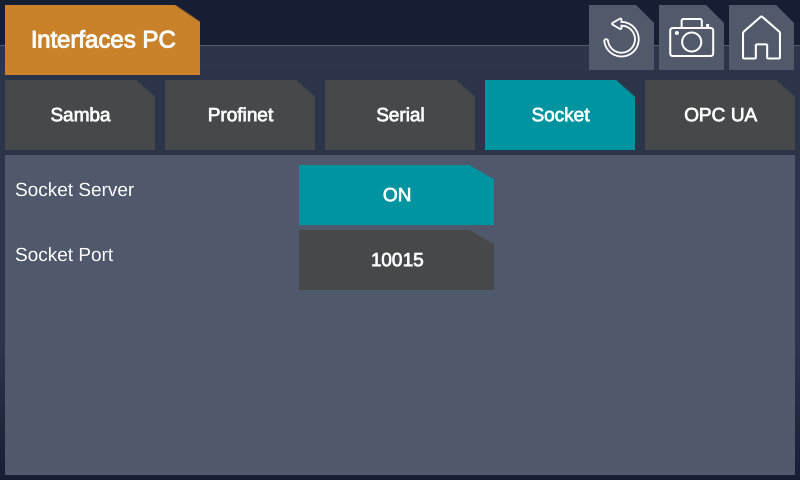

Socket Communication Interface - Custom Control, Real-Time Data

Enable custom automation and control by connecting your LTC-503 to external systems via a standard TCP/IP socket server interface. This extension supports synchronous control and monitoring of tests, parameter settings, and live data queries at 50 ms intervals. It empowers you to develop your own software solutions, HMI interfaces, or integrate with existing management systems. The TCP/IP socket server is available exclusively for the LTC-503 and comes as a standard feature already included in the package. This makes the LTC-503 particularly suitable for developers, integrators and OEMs who want to combine their own systems with a powerful and flexibly controllable leak tester.

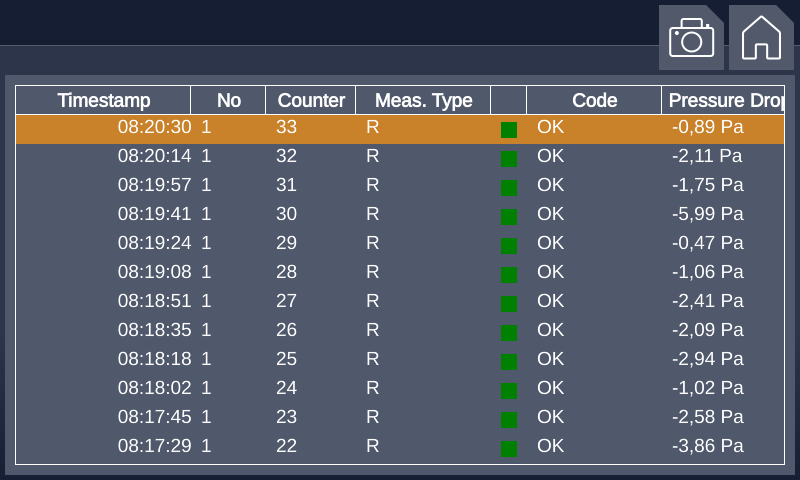

Expanded Data Storage (1 Million Results Ring Buffer) – More Data, More Insight

Upgrade your LTC’s internal memory to store up to 1,000,000 measurement results—ten times the standard capacity—for extensive traceability and long-term data analysis. The expansion works seamlessly in the background, continuously saving test data for audit-ready documentation and in-depth statistical process control. This feature is already included as standard in the LTC-802 and LTC-902 models, and can be optionally added to the LTC-503.

Key benefits

- Handle high-volume series production with strict quality requirements

- Enhance transparency and security across shifts and production cycles

- Support Industry 4.0 initiatives with comprehensive, always-available data

- Avoid extra hardware and ongoing costs with this all-internal memory upgrade

Looking to streamline your test processes?

Contact us to learn more about our add-ons. We’re happy to support you with tailored solutions for your production line.