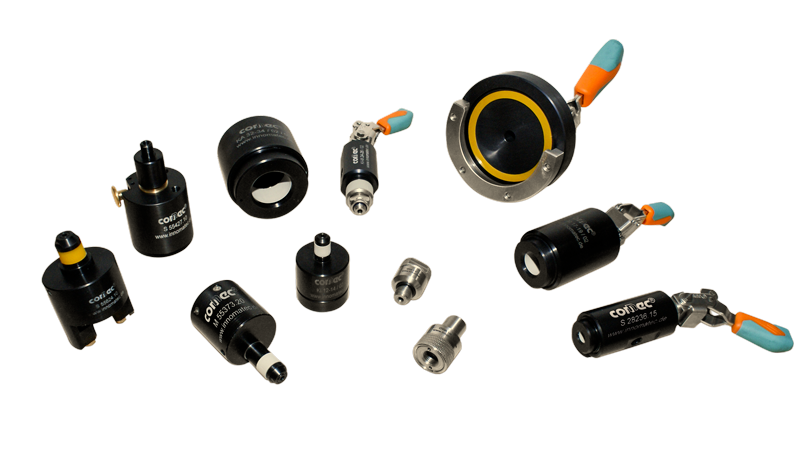

How to choose the right Connec® quick connector for your leak test

Choosing the right connec® quick connector is one of the most important factors for reliable leak testing. A quick connector that does not seal securely can lead to false leaks, inconsistent results, unnecessary troubleshooting, or even damage to the test specimen. A custom-designed quick connector, on the other hand, ensures accuracy, repeatability, and safety throughout the testing process.

Since every application is different—from engine blocks to EV battery housings to medical products—selecting the right quick connector requires a thorough understanding of both the test requirements and the characteristics of the test specimen.

Test medium

The test medium determines which sealing materials and quick-connect designs will work reliably. Air is compatible with almost all sealing materials, but helium or oil require special materials. In addition, liquids such as oil or water reduce the friction of the seal and may require a mechanical retainer/slip lock to prevent the quick connector from slipping. Helium and various trace gases often require double seals in the quick connector with intermediate suction to ensure the most accurate measurement.

Temperature of the test medium

Temperature affects the hardness, elasticity, and wear of the seal. Sealing materials must maintain consistent quality across the entire temperature range of the test. Materials such as silicone or Viton may be required for high-temperature applications.

Test pressure

The test pressure level determines both the sealing material and the mechanical design of the quick connector. Higher pressures require a slip guard/slip lock if the quick connector is not held in place on the test specimen by a device.

Minimum leak rate

Highly sensitive tests require seals with high surface quality and stable, repeatable expansion. Special sealing materials or double sealing concepts may be required for very low leakage rates. The dimensional accuracy of the seal plays an important role in maintaining measurement accuracy.

Test procedures

Different test methods place different demands on the design of quick connectors. Some basic guidelines are:

- Pressure drop (pressure change) or pressure differential methods benefit from a radial seal, as this compensates for scratches or small surface defects and minimizes the force on the test piece.

- When testing with trace gas, double seals with intermediate suction are often required to achieve the specified measurements.

- Underwater visual inspections require quick couplings made of corrosion-resistant materials and, in the case of manual adaptation, a slip guard/slip lock on the quick coupling.

- In a flow test, the quick coupling should not affect the flow cross-section.

Connection dimensions and geometry

The quick connector must correspond to the size and shape of the sealing point. Round openings are easier to seal, while recessed sealing points, thin-walled test specimens, or oval/angular shapes require a specially adapted quick connector.

Interfering contours

Nearby walls, corners, or obstacles can restrict the size or movement of the connector. In confined spaces, compact designs, angled housings, or extensions may be required. Automated systems often use floating bearings to compensate for shaft tolerances.

Tolerances (diameter, axis, angle)

Diameter tolerances are generally easy to handle with elastomer seals, but deviations in axis and angle are more critical. Misalignment can prevent proper sealing. Floating bearings compensate for positional tolerances relative to the test specimen during automated placement of the quick connector.

Surface condition of the sealing area

Surface roughness, scratches, and nicks compromise sealing reliability. Soft seals can adapt to minor defects, while harder seals are required if sealing against sharp edges is necessary. Axial sealing requires a clean, flat contact surface, while radial sealing can also seal rougher surfaces.

Surface moisture

Oil, coolant, or water reduce friction between the quick connector and the sealing surface. Liquids increase the risk of slippage. In these cases, mechanical fasteners, locking devices, or seals with improved grip properties (friction force) may be necessary to ensure a secure connection.

Sharp edges

Sharp or unchamfered edges can damage elastomer seals during insertion or expansion. Harder materials or special sealing concepts can be selected to withstand the cutting forces.

Strength and stiffness of the test specimen

Soft or flexible test specimens, e.g., hoses, can deform when the quick connector is tightened or when they are subjected to test pressure. This deformation can lead to leaks or incorrect results. Support sleeves, inner mandrels, or alternative supports help to stabilize flexible test specimens.

Do you need help selecting the right quick connector?

If you are unsure which quick connector is suitable for your application, our team will be happy to help! Simply provide us with a drawing or STEP file of your test specimen together with your test parameters – or we can discuss your part and your application. Our engineering team will analyze the requirements, identify potential challenges, and recommend the optimal connec® solution – whether standard or custom-made for your process.