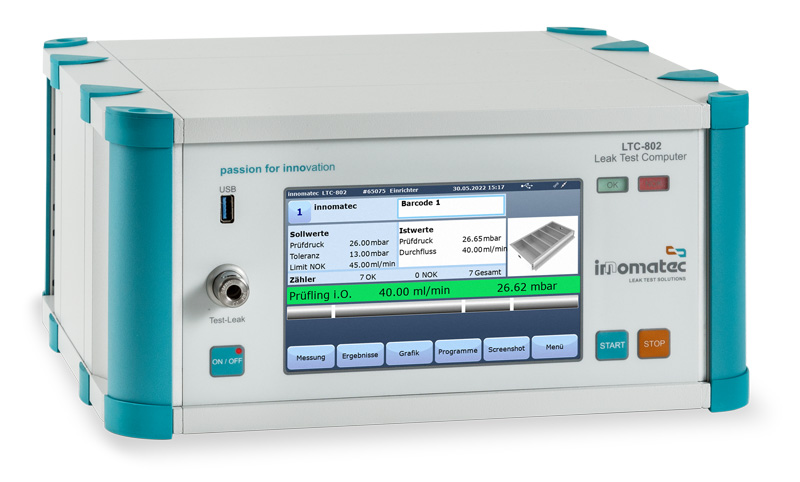

LTC-802

Configurable Single Channel Leak Test Computer

The LTC-802 high-precision leak tester is a versatile single-channel system that provides reliable and repeatable results for a variety of leak testing methods. Unlike other leak testers, the LTC-802 can be tailored to the customer's workflow, providing the flexibility to meet specific requirements. Whether a standard or non-standard leak test task, each instrument is optimized for the resolution and operating range of the part being tested - from small to large volumes, from vacuum to high pressure, from mass flow to differential pressure.

- Versatile and flexible use

- User-friendly operation

- Adaptation to specific test requirements

- Intuitive interfaces

- Integration into production line

Designed to address the needs of today’s factories

The LTC-802’s intuitive interfaces are as easy to use as a smartphone and can be used to control the process whether a PLC is present or not. The leak test computer has extensive communication capabilities to facilitate the integration of leak testing into the production line. There are numerous options for test data management and reporting. With the LTC-802, everything is possible in a single device.

Learn more about the LTC-802 below or contact us to discuss your leak test application.

Types of Leak Test

The LTC-802 is capable of performing various types of leak tests using the following methods:

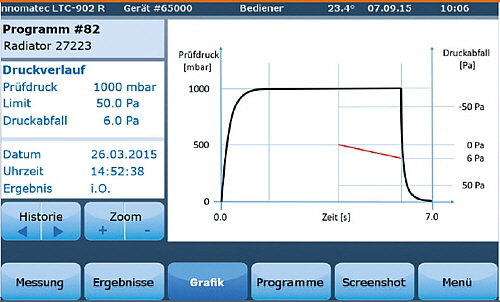

- Pressure change method (A)

- Pressure differential method (R)

- Pressure increase method (S)

- Volume determination (C)

- Closed component method with pressure change method (DA)

- Closed component method with pressure differential method (DR)

- Mass flow method (M)

- Flow method (Q)

- Back pressure and/or blockage test

- Special measurement method

Key Specifications

The LTC-802 offers the right leak testing solution for every application.

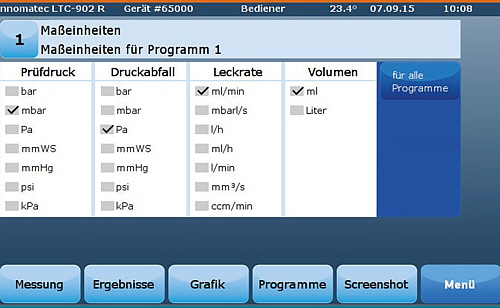

- Evaluation of pressure and/or flow

- Customized sensors and actuators for every type of application.

The main specifications are listed below. For the complete list of specifications, please register to download the LTC-802 Leak Test Computer brochure.

- Test pressure accuracy ± 2 % of control range (other precision on request)

- Test pressure resolution 1 Pa (other precision on request)

- Differential pressure sensor resolution 0.01 pa (other precision on request)

- Flow accuracy ± 2 % of measuring range (other precision on request)

- Pressure ranges 2 mbar absolute to 500 bar relative

- Flow ranges 1 ml/min to 450 l/min (more on request)

- Volume ranges 1 ml to >1,000,000 ml

The LTC-802 offers several options for communication with plant systems. Integration with existing IT infrastructure is easy, and data flow can be structured according to plant policies.

Leak-tight communication protocols

The LTC-802 is a networked leak tester and can communicate over a wide range of network protocols used in the automation industry:

- Digital IO Control

- RS232

- PROFINET

- PROFIBUS

- EtherCAT

- EtherNet/IP

- DeviceNet

- OPC UA

- TCP/IP (RawSockets, ZMQ, activeMQ, etc.)

Custom protocols can be implemented quickly by innomatec's team. Results, diagrams, and pressure curves are available via WindowsShares or FTP.

Supports common peripherals

The LTC-802's PC functionality allows it to connect and exchange data with typical peripherals, such as:

- Barcode scanners

- Part marking systems

- Printers

- RFID readers

Testing made better and easier

- Resistive touchscreen provides easy controlling with your fingers, even with gloves

- Wireless mouse operation

- Control via smartphone / tablet (using browser and WiFi)

The menu navigation meets the latest ergonomic requirements and can be controlled easily and intuitively.

Do you need a multi-channel leak tester?

If you need more than one channel for your application, the LTC-902 is the right choice with many of the same features as the LTC-802.

Let’s find the right leak tester for your application!

Are you looking for a tester that perfectly fits your needs? Look no further, innomatec is the right place for you. Our experts can help you find the perfect leak testing solution for your requirements, no matter how specific they are. Whether you're looking for a more advanced leak test computer or turnkey test stand, we have you covered. Contact us today to get started!