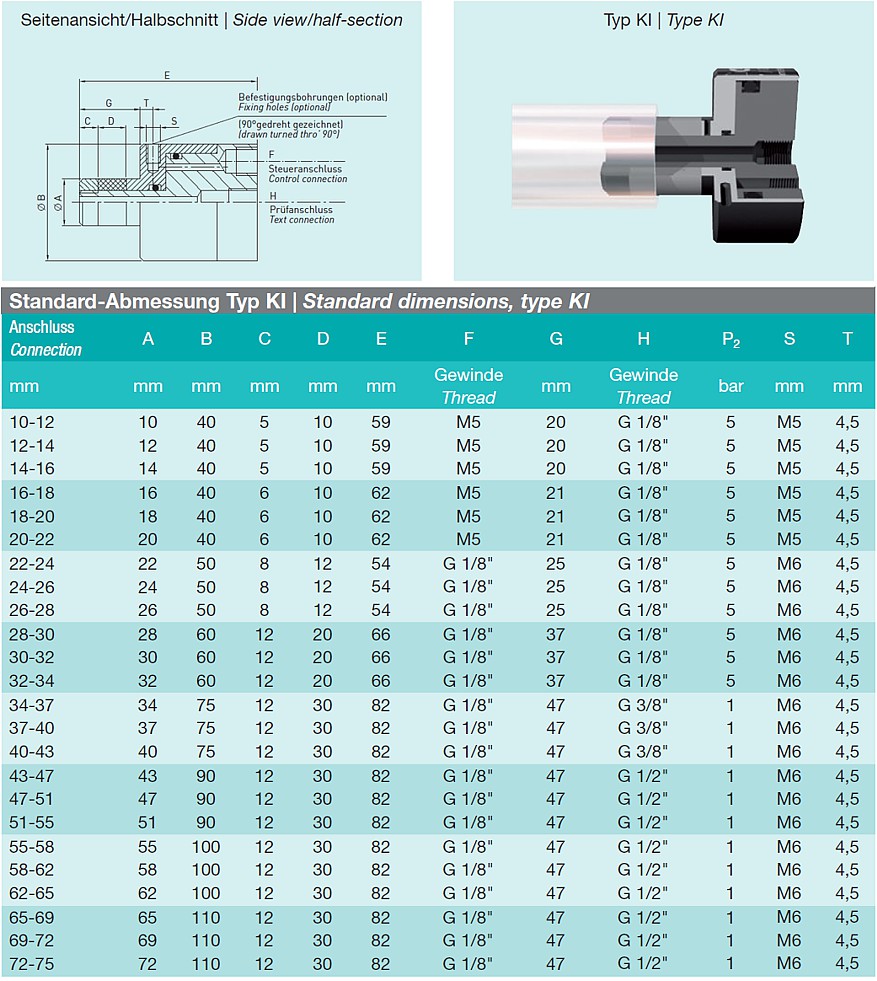

Type KI Quick Connectors for Pressure and Vacuum Tests on Internal Diameters

The innomatec connec® quick connect system, type KI seals bores and connects them to a pipe system. Oval, rough and cast surfaces as well as test specimens with large tolerances of the sealing surfaces are radially sealed.

The innomatec connec® quick connection system has excellent sealing properties ("helium-tight"). The service life of the sealing rubber is designed for suitability for series production. The sealing rubber can be changed very easily without tools.

The connection is available in many special versions for special applications with stroke limitation, slide lock, support sleeve or special seals for special environmental conditions. For special applications, the dimensions of the connection can be adapted to the task. We also offer single pieces.

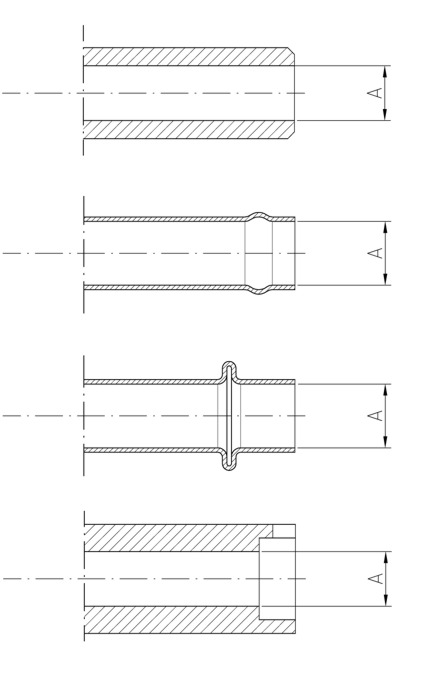

- Smooth bore pipe

- Smooth bore

- Tube with bead

- Tube with flare

- Bore with indentation

Versions

Standard: aluminum, anodised

Special: stainless steel, brass, plastic PA

Control pressure

Type KI - 4.0 bar to 8.0 bar

The connection must always be secured against slipping, unless the sealing surfaces are dry.

In this case, securing can be dispensed with for the working pressures given in the table below (column P2).

Test pressure

-1.0 bar to 8.0 bar

Working medium

Compressed air, helium, water. Other media on request.

Sealing diameter

1.0 mm to 300 mm

The sealing rubber can accommodate diameter differences of 2.0 mm to 3.0 mm (depending on diameter)

Temperatures

10 degrees Celsius to 70 degrees Celsius

Special designs on request

Special sealing rubbers for food and medical applications

Temperature resistance up to 200 degrees Celsius and resistance to aggressive media.

Manual or Automatic Sealing of Inside Diameter with Type KI

The innomatec connec ®quick connection system type KI can be inserted into the bore manually or with an automatic tool. The quick connector is pneumatically activated with control air.

The sealing in the bore is made by an elastic sealing rubber. The system is filled or sealed via the working connection. After the test is completed, the control connection is vented, the sealing ring is released, and the connection can be removed/removed. Depending on the diameter, working pressure or nature of the surface (oily, etc.), the connection must be equipped with a sliding lock.

We can supply the following accessories

- Mounted screw connections for connection lines

- Mounted manual slide valves to control the connection

- Shut-off valves for working medium

- Dummy plugs for working medium

- Floating bearings for mechanical use

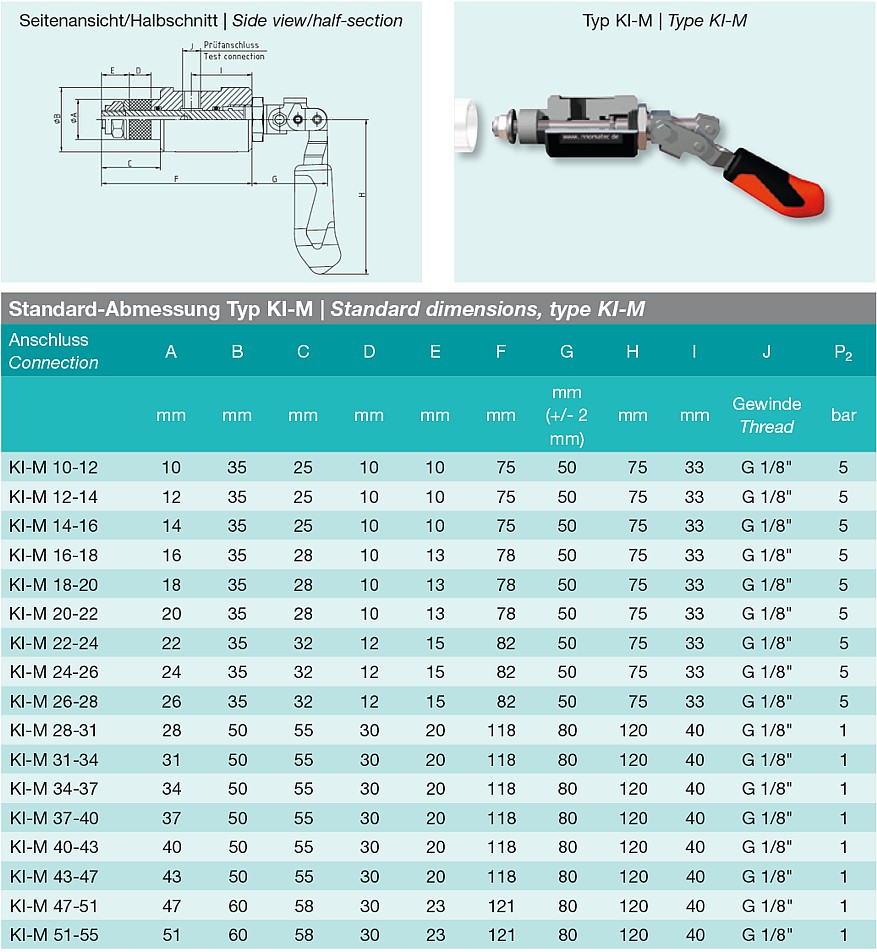

Type KI-M Inner Radial Manual Sealing

The quick connection system type KI-M is inserted manually into the test specimen. The quick connector is clamped by actuating the knee lever.

The sealing in the bore is made by an elastic sealing rubber. The system is filled or closed via the test connection. After the test is completed, the quick connector is released via the knee lever and can be removed. Depending on the diameter, working pressure or nature of the surface (oily, etc.), the connection must be secured against slipping.

We can supply the following accessories

- Assembled screw connections for connection lines

- Shut-off valves for working medium

- Dummy plugs for working medium

Type KI-S-E with Slide Lock for Flared Nozzles

The sealing is done pneumatically at the inner diameter of the test piece. The sliding lock can be locked / unlocked with one hand behind the flare.

From vacuum to 25 bar

- Simple operation of the sliding lock through one-hand operation

- Secure hold due to sliding lock resting on the circumference of the test socket

- Use on nozzles with rough surfaces

Heat exchanger, cooler

Special designs on request. Special sealing materials for food and medical applications. Temperature resistance up to 200 degrees Celsius and resistance to aggressive media.